A new appointment of the column ‘Fashion & Sustainability – Let’s talk’ by RUFA coordinator Guenda Cermel, who this time had the pleasure of interviewing Francesca Polato, Fashion Sustainability Expert of Berto, renowned Italian textile company specialising in the production of high-quality denim fabrics for major Italian and international clothing companies.

The company was founded in 1887 in Bovolenta (PD) and is still run today by the fourth generation of the Berto family.

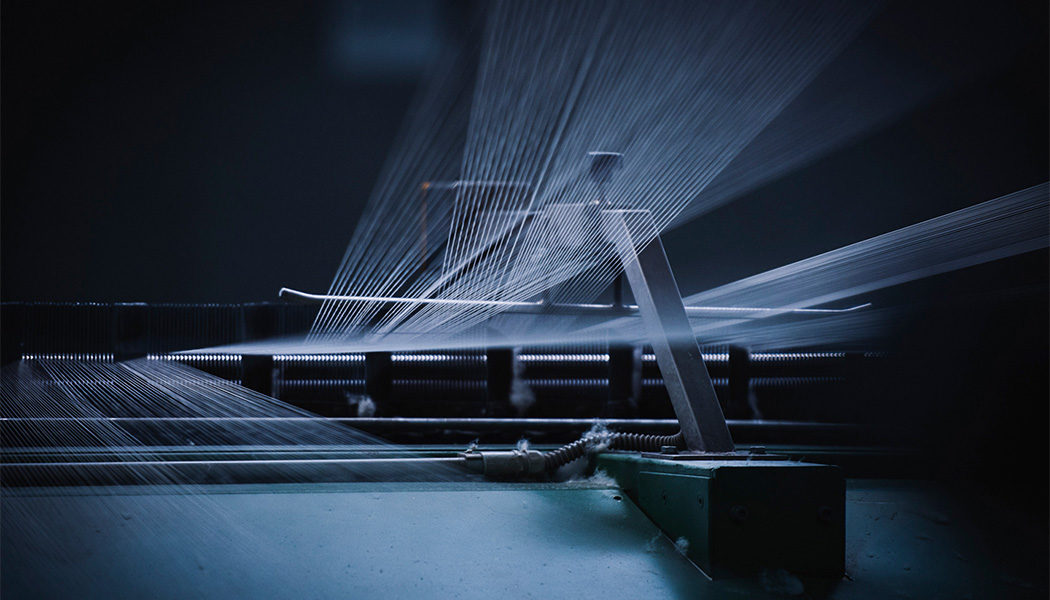

Production still takes place in the historical factories and is an integral part of the Italian textile-fashion chain. We could define Berto as a contemporary craftsman: technicality and manual skill combine with the knowledge acquired over time to create an innovative, high-quality and sustainable product. A company that has been able to introduce profound innovation in the field of denim production, traditionally very impactful, by placing itself in the wake of the ecological transition.

We talked about this extraordinary journey with Francesca Polato, the company’s Marketing & Communication Manager.

Your sustainable philosophy is based on 5 pillars, the 5 R’s: Respect, Reuse, Reduce, Recycle, Repair. Which one is in first place?

“Respect”, and that is why it is in the first place. If there is no respect, it is difficult to pursue all the other goals. The word is understood in two directions:

– Respect for People: the people within the company are the ones who enable us to advance our goals. From the operators in the departments to the employees in the offices, all of them contribute, each with their own role, to the achievement of results.

Respect for them is fundamental. Thousands of people have worked in Berto since 1887. Thousands of families. The company is what it is today thanks to the four generations of the Berto family, still at the helm today, and thanks to the generations of families that have succeeded one another in the company’s departments. Great importance is also attached to the people in the local community, Berto collaborates with and supports various associations in the area.

– Respect for the Environment : the land of Bovolenta has been home to the company for almost 140 years, respecting it is not just an objective for us, but a shared value. The company originates near the Bacchiglione river, which joins the Brenta river and flows into the Venetian Lagoon. The river water is fundamental to our production.

Water is taken and used at different stages of our processes. Once used, it is conveyed to our water purification plant. The result of purification is clean water, which is partly reused in production, and partly fed back into the river, and dried sludge reused to fertilise agricultural fields. We like to think that “we give back to the land what we borrow from it”..

In the 2030 Agenda as many as two of the defined goals concern the conscious use of and respect for this precious commodity.

What has Berto done to come within the parameters of sustainability with regard to water?

As mentioned above, we have a biological wastewater treatment plant. This plant was among the first built in the area. Biological = uses bacteria to purify the water (no chemicals), and allows the sediment (sludge) to be converted into fertiliser. Specifically, this system allows certified biological purification of wastewater, and thus the possibility of disposing of water directly into the environment. This system reproduces in a concentrated and enhanced manner the process that occurs in nature.

We have also been a member since 2016 of the Detox Consortium, promoted by Greenpeace, which aims to eliminate from production a list of chemicals that are harmful to people and the environment. We can proudly say that these substances were already not part of our production.

The Greenpeace Detox Commitment is a public commitment, in fact the results of our water analyses are available and downloadable from our website.

What kind of supply chain is yours?

Our supply chain is European, but predominantly Italian. We purchase our cotton yarn mainly from Italian spinning mills. When we cannot find the product we are looking for in Italy, we also extend our sourcing to Spanish, Portuguese or Turkish spinning mills, for example. Following the purchase of the yarn, the entire process takes place in-house, as we have warping, indigo dyeing, weaving, finishing and quality control departments. If we want to offer fabrics with special finishes (flock, foils, coating, etc.) in our collection, we make use of the collaboration of other specialised companies in the area, so as to support their economy and above all maintain and pass on their know-how.

Where does the cotton you use come from?

Cotton is mainly cultivated by India, China, USA, Brazil… The first European country on the list is Greece, followed by Spain. Our yarn suppliers, depending on the period, needs, quantity and quality of cotton required, source from various countries. We demand (both from Italian spinners and non-Italian spinners) that for our yarns priority be given to European cotton, hence Greek, and that Chinese cotton not be used at all. For every yarn purchase we make, we are always aware of the origin of the cotton used. In recent years, cotton cultivation is returning to Italy; we are in contact with a Sicilian company with which we would like to undertake future projects for 100% Italian denim.

How do you communicate the transparency of your processes to the customer?

For us, the word transparency must precede the word sustainability. There is no sustainability without transparency.

We communicate our decisions and actions via our social channels and official website, and we are ‘in the field’ every day with our sales force, which not only presents all the fabrics in our collection to customers, but also tells them about our sustainable approach.

We are also always ready to welcome our customers to our premises, so that they can visit the departments and see for themselves how we work.

The next step we will take is to draw up a Sustainability Report.

After the pandemic there have been rearrangements along the entire value chain of fashion. As manufacturers, how did you react to the market?

After the pandemic there were several changes. There was a general boom in requests due to the desire to ‘restart’, to reopen shops, to expand the offer for consumers, to which we responded promptly. In addition, there was an exponential increase in requests for sustainable fabrics (made from organic and/or recycled cotton, for example), to which we were fortunately more than ready, since this type of fabric has been part of our collection for years.

Your company represents Made in Italy excellence, what does this belonging mean to you?

Made in Italy for Berto is not just a question of style, but is above all continuity of the supply chain, of the Italian textile industry, of respect for labour and territory.

A long history of textile wisdom and great dedication to work, a unique company that has been able to pass on its cultural baggage and know-how acquired over the years, reinterpreting it in new sectors.

In fact, starting from the production of fabric for sails in nearby Venice, it entered the market for workwear, home textiles, shirts and even denim. This long journey has allowed Berto to become a solid company, with a wide and deep product range, and above all a production flexibility that guarantees highly customised products.

Tradition does not mean continuing to do things the way they have always been done, but having the true cultural source of know-how; hence in Berto tradition and innovation are not enemies, but allies, and they interface thanks to a virtuous contamination.

With the courage to listen to the prevailing laws of the world market, but always innovating while respecting tradition, we have succeeded in finding the right place within an international panorama, combining the Italian craftsmanship approach with the most modern industrial logic. We were able to achieve this not only through our own efforts, but also by collaborating with other specialised textile companies in Italy, so as to support their economy and above all maintain and pass on the know-how of the great Italian textile world.

Finally, a fashionista question. Is there a type of “quiet luxury” denim fabric?

In which direction are your customers in the luxury segment moving?

The classic 100% cotton medium-weight denim is the epitome of quiet luxury. A trend that has emerged in recent times for those who want to ‘dare in silence’.

Denim is par excellence that fabric you wear when you want to be a bit more sporty, informal, relaxed, but just pair it with a black blazer and add an it-bag and suddenly the look becomes “quiet luxury”.

In this look, I imagine a fluid jean, perhaps with a palazzo cut made from a non-stretch fabric, 100% cotton or in ‘blend’ with some cellulosic fibre that gives additional fluidity and softness to the fabric

The weight of the fabric must in any case be medium to high to give structure to the garment. In our collection, to achieve this, we use yarns made from high quality, ‘long-staple’ cotton to ensure softness and comfort even in heavy fabrics. Our yarns are then dyed with pre-shrunk liquid indigo, which is perfect for obtaining bright and deep wash tones, essential for creating a quality denim garment that is perfect for a look“quiet luxury”.

FIND OUT MORE ON BERTO INDUSTRIA TESSILE